Semi Automatic Filling

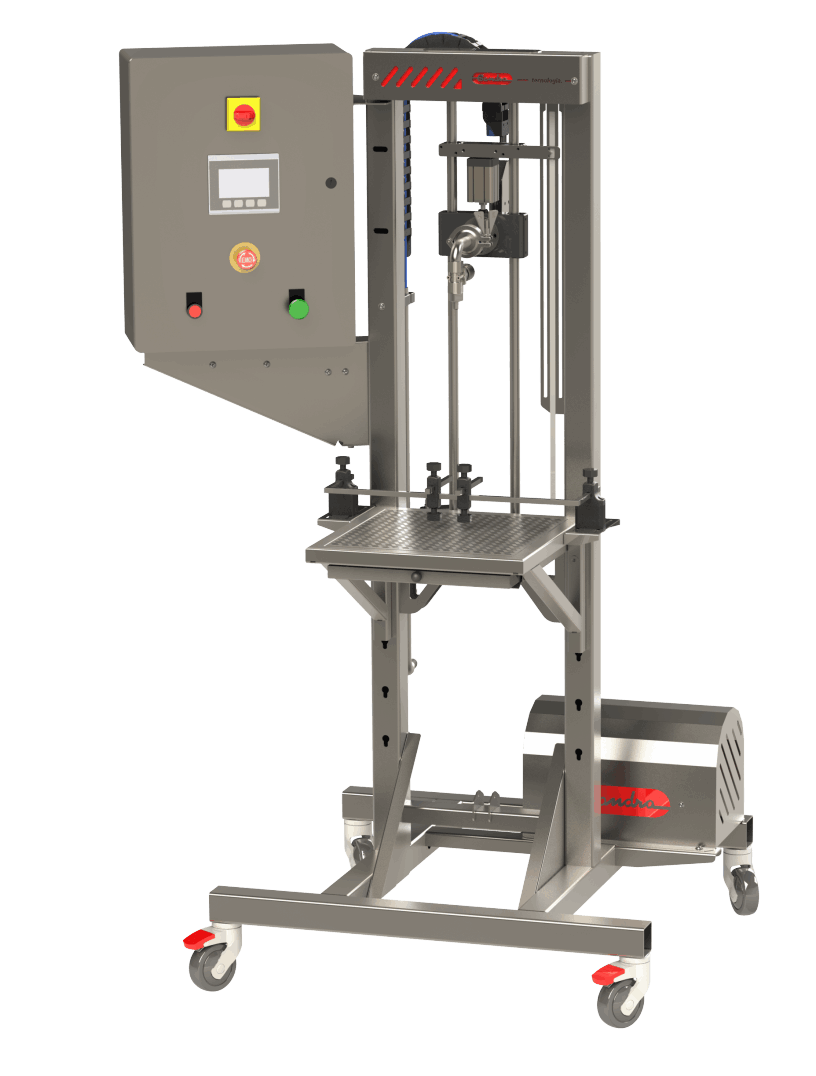

Unit filling for different types of packaging, the models developed by Gandra, become an excellent tool for those who need a precise, effective and versatile dosing solution.

The equipment is capable of dosing the most diverse types of containers and can be used with products such as: olive oil, detergents, juices, etc.

There is a scale version controlled by load cells, and a flow version controlled by a flowmeter.

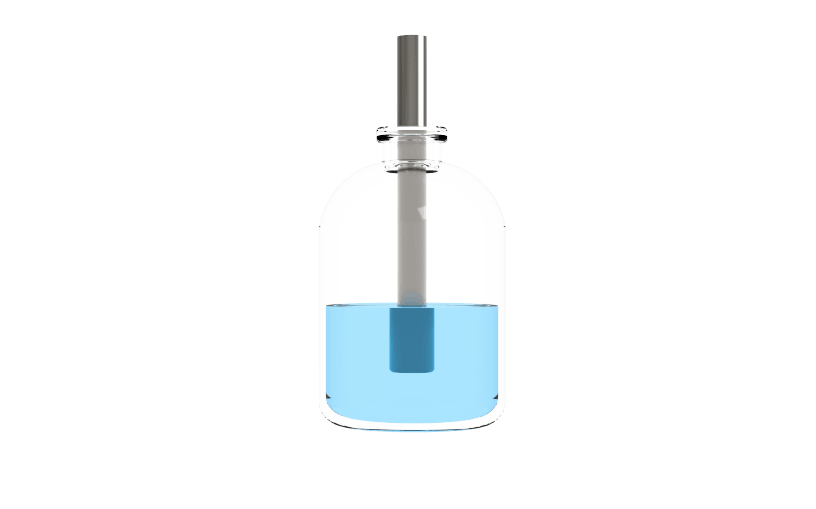

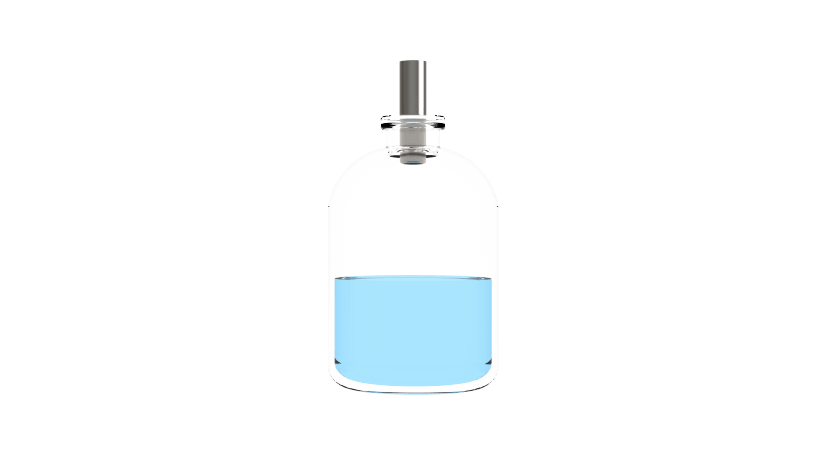

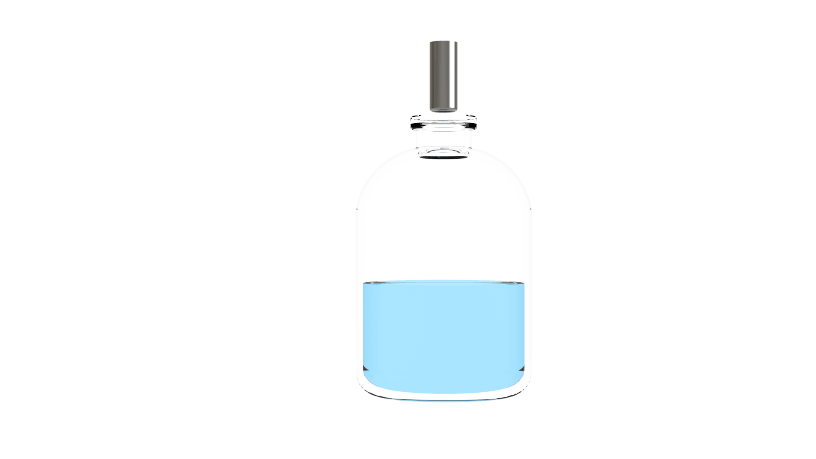

The filling valve varies depending on type of liquid to be dosed. Below it is possible to check the different types of filling.

With the option of coupling a capping system (see the video below).

Main Advantages:

- Compact and low space requirement;

- Quick and easy valve cleaning;

- All filling systems are properly calibrated and ready to go;

- High variety of packaging.